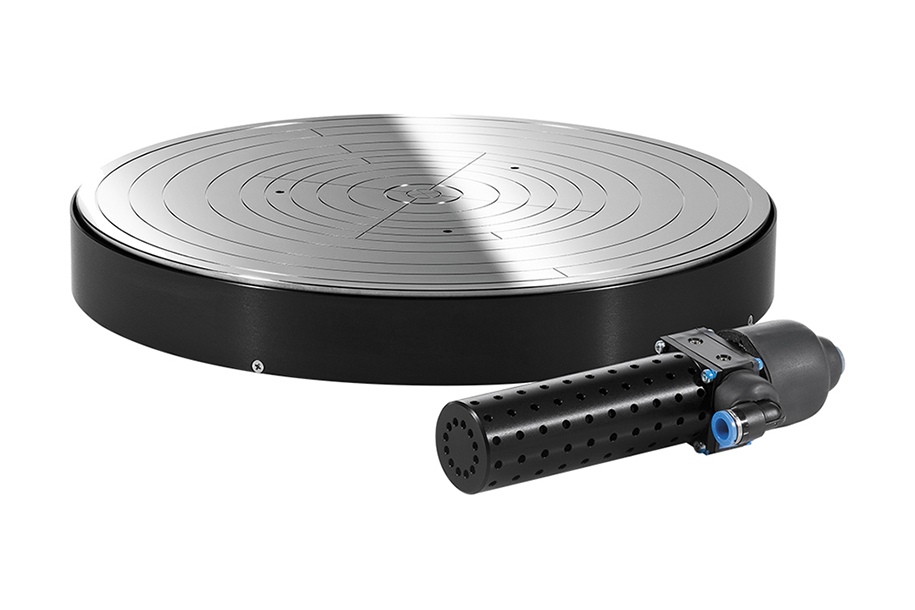

Why choose an ERS chuck system

As a quality and technology market leader ERS has a clear statement for product features: Uncompromised excellence in all disciplines. The advantages offered to the semiconductor industry by our chuck systems shows that we have kept this statement in mind during all stages of development and production.

7 REASONS

Superior chuck flatness

Maximum surface flatness ensures ideal contact area for the wafer. The extremely rigid ERS chucks are easily able to withstand the thermal and force stresses encountered in the use of high pin-count probe cards.

Wide temperature ranges

ERS chuck systems are available for both extremely high and extremely low temperatures. For analytical probing applications, ERS also offers various temperature ranges between -65 °C to +550 °C.

Rapid temperature ramping

For analytical and production test applications calling for fast temperature change, cooling and heating times become particularly important for wafer test throughput. ERS’ know-how in heat-exchanger technology and air flow management are behind the fast ramping times.

High temperature precision

Constant temperature distribution across the ERS chuck assures that the same base conditions apply to every chip on the wafer during test. ERS systems typically offer temperature uniformity of better than ± 0.5 °C across a 300 mm chuck.

Low electrical noise, short settling times

Experience in test measurement technology provides ERS systems with the best electrical performance on its chucks. Additionally, the use of low-noise DC temperature controlling and electrically quiet air-cooling ensures that the systems are suitable for testing in the femto-Ampere range.

Reliability and exceptionally long lifetime

Air-cooled systems from ERS have recorded MTBF values of more than 50,000 hours – almost six years uptime without interruption.

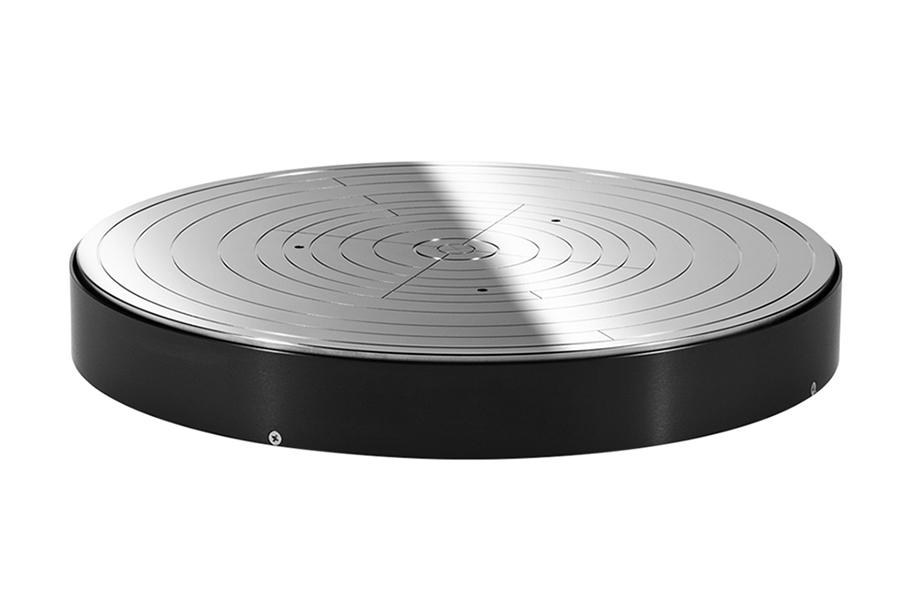

Minimum space requirements

Thanks to the AC² efficient heat exchanging technology, ERS chillers can provide chuck temperatures down to -65 °C at an impressively small footprint unmatched by other thermal wafer chuck systems.

The patented AC² technology also allows for a high degree of integration into industry standard wafer probers, further shrinking the clean room footprint.