Last week was Earth Week, and together with more than 400 companies, ERS participated in the Time for Climate Action campaign and introduced its Sustainability Initiative to the public. Sophia Oldeide, who has been appointed as Climate Officer, told us how this initiative came about and the process of coordinating and managing ERS’s journey towards climate neutrality.

Last week, ERS announced its Sustainability Initiative, with an ambitious target of reaching climate neutrality by 2030. Where did this push come from?

Sophia: I think several factors led us to introduce this initiative. The semiconductor industry, which we’re a part of, is an extremely energy- and resource-intensive industry, and I don’t think it’s possible to ignore this fact anymore. The sooner a company decides to take some responsibility for that, the better. Laurent, our CEO, has been a key driving force behind the initiative, which we started working on about a year ago. We spent a lot of time trying to figure out how to best address the topic of sustainability as a company, both internally and externally. However, with 60 employees, we don’t have a dedicated department or person that can solely focus on this aspect of our company, so we were looking for guidance and advice on best practices for reducing our footprint and improving our sustainability performance instead of having to start from scratch. Then, by coincidence, we found out about the organization, Leaders for Climate Action, which offered exactly what we needed to get started.

How did you learn about the Leaders for Climate Action (LFCA) organization, and what was the process of becoming a member like?

Sophia: We heard about the Leaders for Climate Action organization last year from one of our board members. We quickly realized that it was a great opportunity to learn from other companies who are facing the same challenges and moving towards the same goal as us. Our CEO applied for membership for himself and the company, and then we had to take the “Green Pledge” to receive the company membership. As part of the Green Pledge, we were required to calculate Scope 1 and 2 and parts of Scope 3 to measure our footprint in 2021. For the measurement, we used a carbon estimator tool developed by the LFCA. It was quite challenging to gather all the data needed, for example, for the measurement of our yearly emissions from employee commuting. However, this turned out to be a great way to get the whole team engaged in the initiative. I created a survey and asked everyone to input their means of transportation and commuting distance, and ended it with a question about how we, as a company, can incentivize employees to choose more environment-friendly transportation options. We got a lot of good input and suggestions, so we’re currently working on an incentive package and hope to introduce it soon.

What do you expect will be the biggest challenge moving towards net-zero emissions?

Sophia: A considerable challenge for us, and I think a lot of companies in general, will be to measure our full scope, especially Scope 3, which comprises our entire value chain. Getting access to and collecting these data alone will be a massive task, and then we will also need to analyze everything. It will definitely require a lot of effort, but I believe it is necessary for us to be able to identify the emission hotspots and areas for improvement. Fortunately, there are a lot of useful resources available. The LFCA community is, of course, one of them, but many of the member companies are operating in other sectors and have very different business models, so their approach doesn’t always fit with our company. Another great resource is 3D InCites, where we are also a member. They regularly post articles and insights from the semiconductor industry, and many of them discuss exactly this topic. The SEMI organization also offers several events that put sustainability at the center and bring together companies to discuss how to address industry-specific challenges.

You have mentioned some “internal” measures that ERS is undertaking. As an equipment supplier with a large footprint in the wafer test industry, are you also investing in the development of more sustainable products?

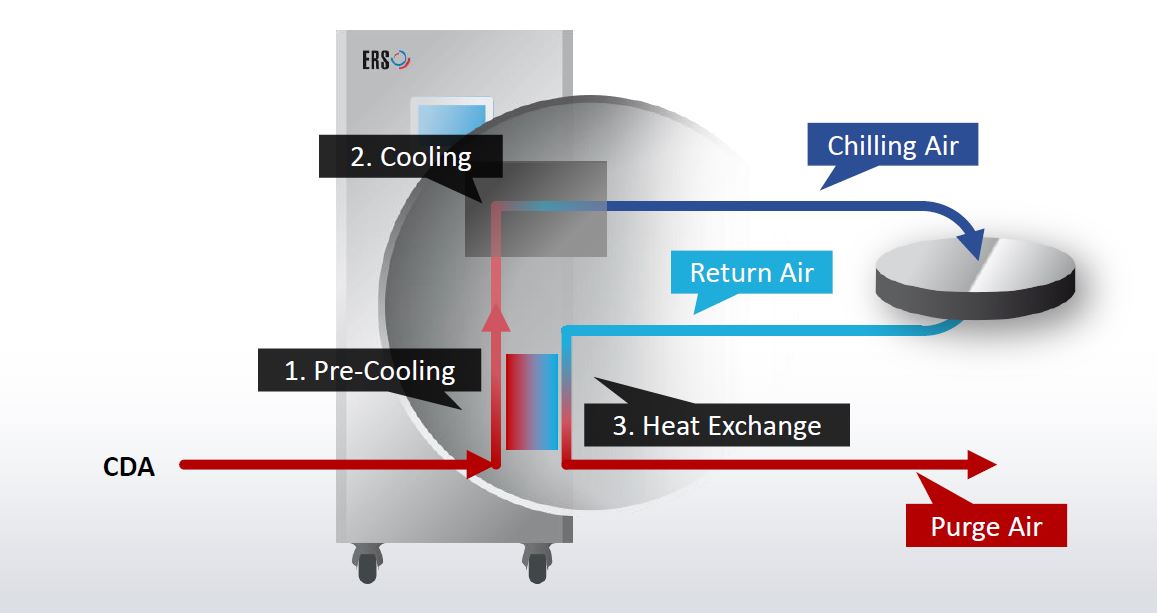

Sophia: ERS has always had a focus on sustainable innovation. In the 90s, we were the first company to start using Clean Dry Air (CDA) instead of liquid and Peltier elements, which both leave a much larger environmental footprint. By the early 2000s, ERS developed a technology that enabled the recycling of the air for pre-cooling, cooling, and purging, which has become a core technology of our AC3 thermal chuck system. We are still very much aware that temperature test in wafer probing is an energy-intensive activity, independent of which cooling method you use. However, sustainability continues to be an important aspect of our product development, so when we assess new ideas, we also consider how we can reduce the environmental impact of each potential new product. Our latest technology for wafer probing, the AC3 Fusion, is a great example of this approach.

Finally, do you have any advice for other companies that are thinking of doing something similar?

Sophia: I think my best advice is to just get started and not hesitate to take advantage of the many available resources. We have access to reports and data that companies and organizations share publicly, and these can be a great source of inspiration and information. I also recommend regularly communicating with your colleagues on the topic and asking them for ideas and input. When I brought up the initiative with our team, I immediately received a lot of positive feedback and suggestions. It was great to see how much it resonated with them. To me, it also means a lot that we choose to take action and be vocal about it, and it’s great to know that I have the full support of the management team and my colleagues and can go to them for help whenever it’s needed.