Joshua opened our office in Shanghai in 2018 and was promoted to Vice President of ERS earlier this year. In only a little more than three years, he has built a solid team and significantly increased the presence of ERS in the China region. Today he is presenting our thermal solutions at the China International Semiconductor Executive Summit, which is one of the top semiconductor events in the country. During his preparation for the summit, we talked to him about his journey so far with ERS Greater China and his outlook on the Chinese semiconductor industry.

Q: Throughout your career in the semiconductor industry, you have worked with global players like TI, but also local Chinese actors like Hangzhou Nanosic Tech. What brought you to ERS, and what are the differences between working for a Western and a Chinese company?

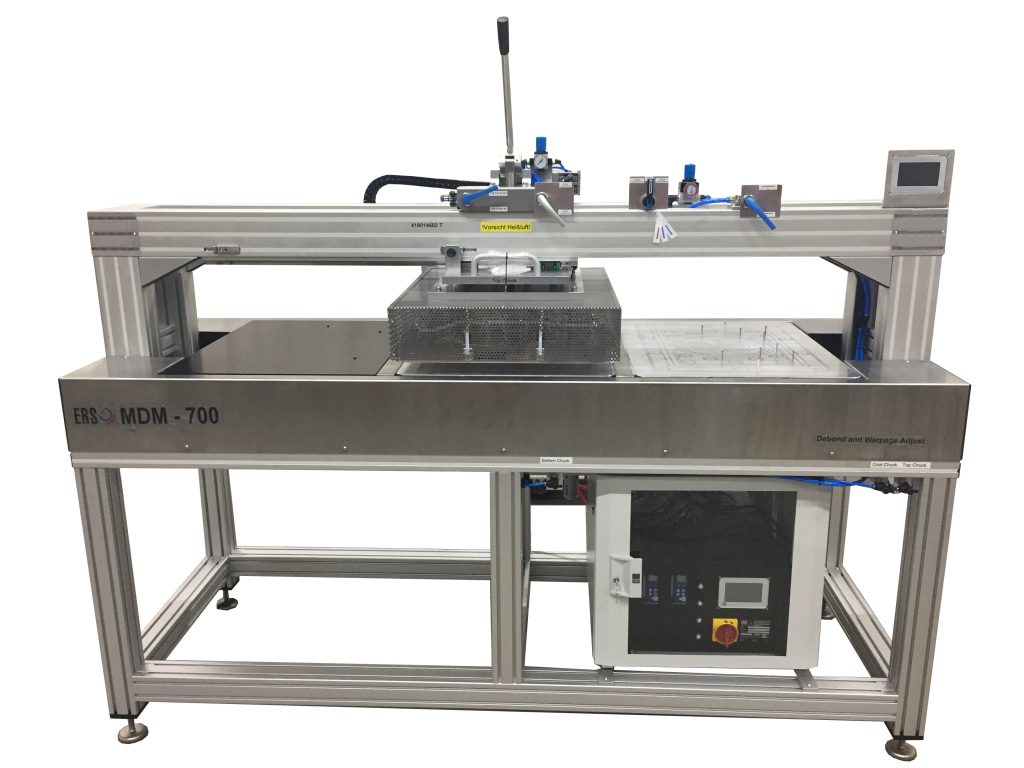

Joshua: In the companies I previously worked in, my job was to promote and sell semiconductor devices manufactured in US and China. I chose to work for them for the same reason I was attracted to ERS; because of their great reputation in the industry for providing advanced solutions. ERS has long been known as a manufacturer of thermal chuck systems for wafer probing, but they also have a long experience with thermal debonding and warpage correction for eWLB and other Advanced Packaging technologies. These products are in high-demand in the Chinese market, so I saw a great potential for an expansion of ERS in China.

There are of course many cultural differences between Western and Chinese companies. I’ve noticed that in business Germans are usually very straightforward, so their focus is on getting to know the customer and doing their job. In China, there are more factors you need to take into consideration. For example, you need to be mindful of your appearance when building relationships with your managers, bosses and partners. So I would say that life is simpler when working for a Western company (laughs).

Q: You opened our sales office in Shanghai in 2018 as Sales and Marketing Director of ERS Greater China. Today you are Vice President of ERS and in charge of a team of four people, providing not only sales, but also technical support for our Thermal Chuck Systems and Fan-out machines. How did ERS achieve this in only three years?

Joshua: One of my first big tasks after opening the office in Shanghai, was to build relationships with local distributors, like Spirox Technology and Jinni, to create a strong sales and distribution network in the country. Three months after I joined ERS, we attended SEMICON China, which was a great way to get to know the Chinese industry players. Since then, we have also increased our attendance to other local events, like SYNAPS, which is an Advanced Packaging Symposium hosted by NCAP, CSPT, and most recently we have announced our attendance at the China International Semiconductor Executive Summit. Attending these events is absolute key in broadening our reach. And of course, the most important has been the addition of key team members. We are now a team of five, providing sales and order processing, design and project management, and technical support for both Thermal Chucks Systems and Fan-out machines. Although we all speak Chinese, we have different backgrounds, which I think makes our team unique. One has studied and worked in Germany for a long time, another one in Canada, and some have long experience working for American and Japanese companies. What we all have in common is a passion and willingness to win business, which I believe has been crucial to our achievements so far.

Q: And how have the Chinese customers responded to the team so far? What is the most common feedback you receive?

Joshua: What I often hear is that we are a good representation of German high quality innovation, and that we have a great production process. In China, the “Made in Germany”-brand is known for high quality, and that is what they get when they choose ERS. A lot of people think that China only wants low cost, but that is not the case, especially not in the semiconductor industry. Chinese customers want the best product. So after identifying the product they want, they seek out the right people to talk to. Then the price is discussed.

Our customers also appreciate our focus. We don’t have a very broad product line, instead we use our expertise and experience to identify the right product for the right market, by working with local prober makers and IC fabless. Another very important thing is honesty. We tell people the truth. Some companies say that they can do everything, but that can end up hurting the company’s credibility. We are very honest with our customers about our products and capabilities, which has helped us build a good reputation among customers and in the market over the past few years.

Q: The Chinese semiconductor industry is developing at a rapid pace and is approaching self-sufficiency. How can international companies remain competitive in the Chinese market?

Joshua: It’s true that China has increased investment in its domestic industries and accelerated its pace of innovation to reduce the dependence of the global semiconductor industry, but it doesn’t mean everything will be produced in China. IC manufacturing contains lots of complicated processes including design, packaging, assembly, test…each step requires numerous production equipment and manpower. Especially considering the cost, it’s almost impossible to rely on a single country to complete the whole IC production process. The Chinese semiconductor industry always opens its door to those companies that have advanced technologies. Therefore, an international company that wants to remain competitive in the Chinese market must firstly listen to local customers’ demands, work with local partners, and then provide your cutting-edge technologies and products to them.

From the perspective of after-sale service, the capacity of providing on-site support is very important in this fast-paced industry. Companies don’t have time to wait several weeks for technical service. Shipping defective products for repair is both time-consuming and expensive. The Covid-pandemic has already shown that we cannot rely on travel overseas and has highlighted the importance of building a local support team.

Q: Where do you see ERS Greater China in 5 years?

Joshua: I see ERS Greater China continuing to grow for the next 5 years. Providing more innovative products and local customized designs are the key factors to accelerate this expansion. To achieve that, establishing a China R&D centre seems imminent. Beyond that, throughout the market, renewable energy and batteries will continuously be popular topics in the following years. As a thermal chuck manufacturer, developing economical high power wafer test solutions is crucial to sustaining competitiveness in the market. On the other hand, although the high demand for complex IC applications and the aim for miniaturization put Fan-out packaging in the limelight, its noted advantages still came with significant costs. As a cost-effective strategy, large panel format is imperative and is expected to boom in China in 2-3 years time. We introduced our thermal debonding technology for panel level already in 2019 with the MPDM, Manual Panel Debonding Machine. I am looking forward to introducing its automatic version APDM to the China market, which will become another breakthrough of high-volume production in the Fan-out advanced packaging industry.