Regine Beckmann is our Regional Sales Manager for Europe and Asia. We talked to her about the recent activity in Europe following the EU Commission’s announcement of the EU Chips Act, and how ERS may help OSATs and manufacturing companies establish in the region.

Q: Before joining ERS, you previously worked for Nitto, a Japanese company. How was the transition from a larger, global Japanese corporation to a smaller German SME? Were there any valuable lessons learned from this experience that you brought with you to ERS?

Regine: It’s true that Nitto is a big corporation, but its semiconductor department in Europe is relatively small, so in that sense, it wasn’t such a big change coming to ERS. Usually, in bigger companies, there is less direct contact with the upper management, but in the European semiconductor division, it was a bit different, so I often had direct communication with the managers in Japan. Also, by Japanese standards, Nitto is not a conservative company; it’s known for having a very open culture. The same applies to ERS. When I started working here, there were about 40 employees, so everyone knew each other, and you often worked across several departments. Today, although we’ve considerably grown since I joined, that flexibility in interaction is still very much there. In big companies, structure is a must, and this is especially true for Japanese companies. They value clear structures with strong boundaries, and they pay great attention to details before they come into action. This process usually takes a lot of time, so you need to have patience, but in the end, you can be sure that the result is high-level. This is really one of the merits of Japanese culture, in my opinion.

At ERS, there is more room for flexibility, which is good but can also come at the expense of structure. So that’s something we are continuously working on as we are growing, and which we have improved a lot over the years, for example, with the introduction of a CRM system.

Q: You’re the Sales Manager for several regions, including Europe. On February 8th, the EU Commission introduced the EU Chips Act, and Intel recently announced a huge investment in Europe. What is the current “atmosphere” among our German and European partners and customers? How do you see it affecting the European semiconductor industry?

Regine: I think we are all thrilled that the semiconductor industry is finally in focus, and it’s great to see that the EU commission realizes the importance of semiconductors everywhere. We already saw several investments in the last years, with Infineon and Bosch both opening 300 mm fabs in Austria and Germany. Vishay also recently announced a new 300 mm fab in North Germany, and in Italy, STMicroelectronics is building a 300mm fab in Agrate. Now it has to be seen what additional growth effects the EU Chips Act will bring. Whereas front-end fabs are well established, a positive impact on bringing chip packaging production back to Europe would be an asset in regards to independency.

One of the big challenges in view of this planned growth is finding skilled people. So I see this as an important task of our industry – bringing across the message that the semiconductor industry offers exciting and stable career opportunities.

Q: Last year, you attended SEMI Europe’s Packaging Technology Seminar. What were the key takeaways from this seminar, and how do you see the role of Advanced Packaging evolving in Europe?

Regine: Among the participants at the seminar were Fraunhofer IZM and Dr. Tanja Braun. She started the Panel-level Consortium a few years ago, anticipating this as an important topic in Europe, but putting it in a global perspective by involving players from all over the world. So this concept could be seen as coming from Germany with Fraunhofer IZM’s initiative. However, back-end and packaging are still seen today as an Asian domain, and this won’t be transferred to Europe from one day to another, so it is definitely a long-term topic. One of the takeaways from the conference was that we might see smaller OSATs for specialty applications establishing in Europe rather than one big one. It’s too early to say for sure what will happen, but we are hearing about activities going on behind the scenes that are not yet out to the public. For that reason, I see a lot of potential for our manual and semi-automatic machines in Europe. Companies that are establishing themselves in the region will need a flexible partner that can provide a variety of solutions, for example, research or prototyping, and this is where we come into the picture. We offer a unique technology for warpage adjustment that leverages our know-how in temperature management and addresses a very big issue with Wafer- and Panel-level packaging. As I mentioned, we are also a flexible company, so we’re not only limited to classic debonding, but we can also deal with panel-handling that needs heat, for example. We are also open to all inquiries and look to find the best possible approach to each challenge.

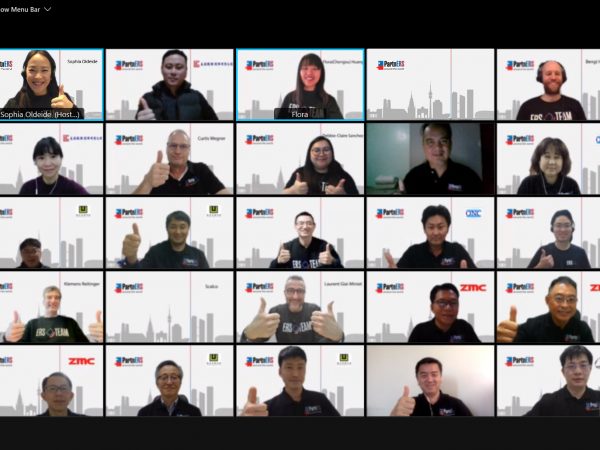

Q: We recently had an online meeting with our global channel partners. How did it go, and what was the main message of this meeting?

Regine: The two-day global partners meeting went very well and exceeded our expectations. We were a bit worried that people would be less engaged because the meeting was online, but there were lots of interactions and questions. I also believe that the meeting was held at a good time – at the beginning of the year and with very strong new products in the pipeline. Furthermore, we are in a period of growth where we see plenty of opportunities to expand our business. So It’s a good kick-off, driving them to go to their local markets, bringing our products to potential customers, and getting their business.

Q: Do you think that online meetings will be the future? Or will we go back to doing in-person meetings?

Regine: It is true that with virtual meeting tools, you can meet people worldwide without long travel preparations and time-consuming trips. Especially with the global pandemic, many companies have taken the habit of working remotely, knowing that they are able to collaborate and communicate online as easily as meeting in-person one-on-one. However, despite the numerous benefits of an online meeting, I think personal contact cannot be replaced. Without having everyone in the same room, you can’t react to their body language or feel what mood they are in, which could change the whole experience of presenting your firm or a product. Small talk is also missing in the online calls, which is important to strengthen personal relationships.

In today’s technology-connected workplace, physical meetings may be less common, but they are still very necessary because you cannot convey feelings on a computer screen alone. I believe a combination of online- and in-person meetings will be applied in the post-pandemic time.