Bernd Krafthöfer is the Sales and Marketing Director of ERS Americas LLC and is based in Dallas, Texas. In the midst of his preparation for SW Test San Diego, which is the first in-person conference he is attending after a long period of strictly virtual events, we talked to him about all that’s happened in the last 18 months, as well as some of the projects he is currently working on.

Q: Throughout your career, you’ve worked for big semiconductor vendors, like Texas Instruments, Diodes Inc., and ams AG. How was the transition to a smaller company like ERS, and how does it compare to the other positions you’ve held in your career?

Bernd: My first job after I finished engineering school was for a small Munich-based company in the semiconductor industry with about 60 employees, so when I started working for ERS in 2018, it actually felt like going back to my roots. What attracted me to ERS was its long history of being an innovator in its field, and it’s quite amazing to think that a small company has such significance in the semiconductor industry. We also have a very international team – I think more than 20 different nationalities – meaning you get a lot of different influences, and so you don’t really think too much about the size of the team.

What I’ve found throughout my career is that it doesn’t really matter whether you work for a company with more than 30.000 employees or a company with less than 100. In big companies, it’s not like you ever get to work with all 30.000 people. You work with a subset of people, and that group of individuals determines whether you’re successful or not.

Q: But a lot has changed in the past 18 months when it comes to how teams work together, with a lot of people switching to home office. You’re based in Dallas, Texas, so you’re no stranger to remote working. How does this influence the way you work with the team in Munich and your customers, and how has it changed since the COVID-19 outbreak?

Bernd: I would say I have quite a lot of experience working remotely, in the sense that I have worked from an office, managing teams and interacting with people from all over the world. However, working from home is something different because you don’t have anyone to discuss with or bounce ideas off of or just get a coffee with. So when the pandemic broke out, and many people from our team had to do home office, I felt that it brought me closer to the team in Germany. Suddenly, we were all in the same situation, and we could all empathize with each other. The way our team quickly embraced and adapted to using video conference and collaboration software, like Microsoft Teams, also made a huge difference. Before, I would talk to people on the phone or communicate via emails, but now with Teams, I am able to see the person I’m talking to. This may be my personal preference, but I find it so much better because I get to see that person’s reaction, be it a customer or a colleague. The downside, of course, is that I haven’t been able to say to customers, “Hey, I’ll come visit you next week.” Then the answer would be, “No, sorry, we are not allowing any external visitors.” Scheduling from a service perspective, bringing in people from another location was a huge challenge that was experienced everywhere during the pandemic, not just in the US. Sales is easier in that way because you can work through most of it online.

Q: In addition to a pandemic, the world is also experiencing a chip shortage, which has put pressure on not just the chipmakers but also the whole supply chain. What are the biggest challenges currently faced by equipment manufacturers? And how can we best meet our customer’s demand?

Bernd: Well, the chip shortage is a result of the just-in-time production that we have created. What the chipmakers need to do is to invest in enough equipment to the extent that they can meet the current demand. The whole industry has worked in cycles, where you go through periods of too much, too little, too much, too little. I’ve been through several of these cycles throughout my career. And as an equipment manufacturer, I can say that communication is absolutely key in these kinds of situations. That means planning and understanding what the customer needs are and doing our due diligence in forecasting so that we can communicate back to our vendors what our needs are and avoid falling behind on commitments. It also means committing to innovating and bringing new technologies to the market so that they can rely on us to make the best equipment for testing their products.

Q: Can you say anything about some of the customer projects you are working on right now? Which big trends are you seeing in the industry at the moment?

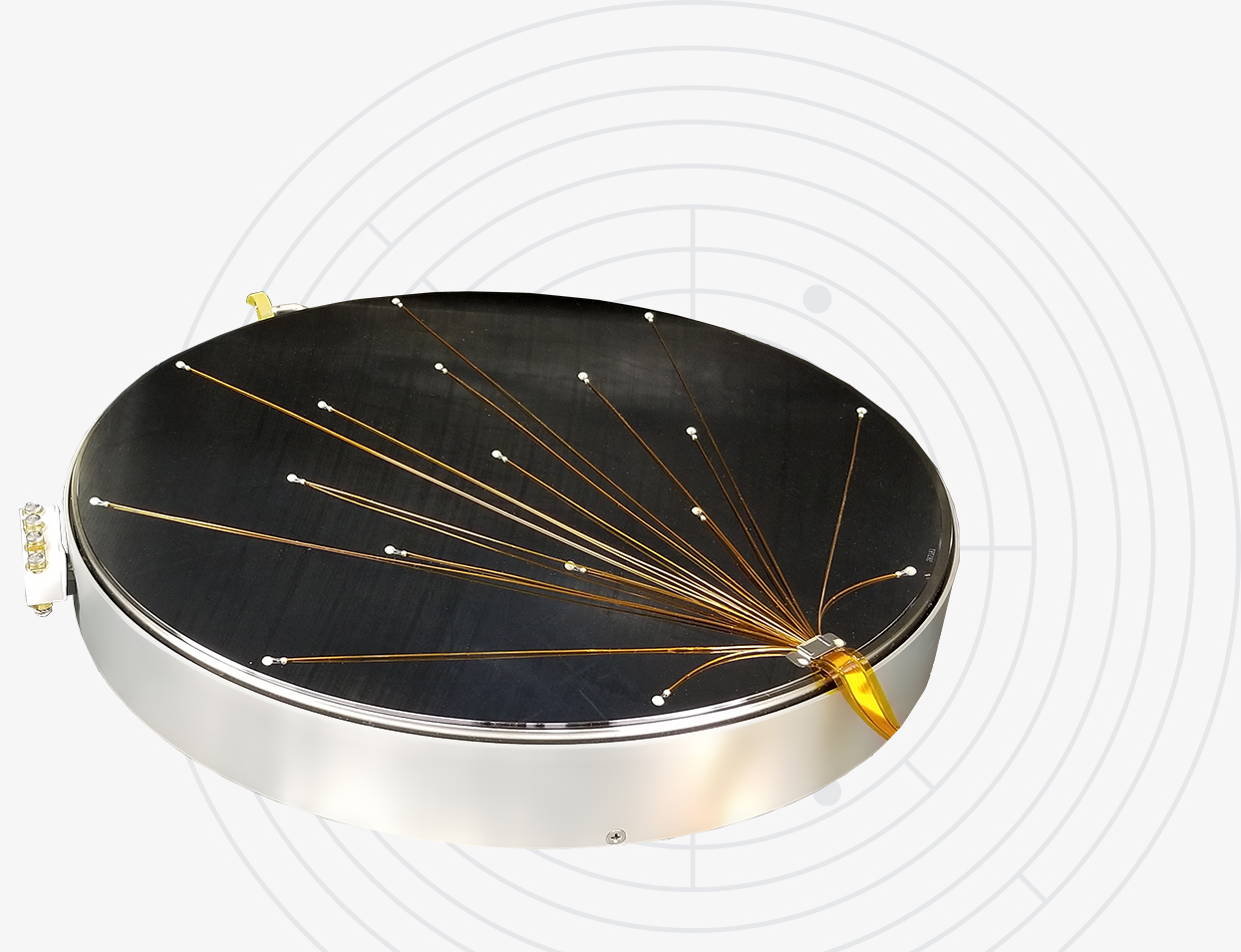

Bernd: We see high demand for test equipment for substrates like GaN and Silicon Carbide. We also see that customers want to understand earlier in their production process; basically, right after the production of the wafer, they want to determine which chips are good and which chips are bad. The trend with more electronics in automotive means that more chips are being exposed to temperature extremes, and those extremes are also expanding. So this is where we come in. We offer very tight temperature accuracy over a wide temperature range from -55°C to 300°C, and we see high demand for this coming from the development of self-driving vehicles. A lot of sensors are being produced for the computer of the vehicle, and they need to work in these extremes, so a lot of testing is being done for automotive applications. It’s important that all the chips on the wafer work equally well, so maintaining a high temperature uniformity on the probing stations is a big topic which we have addressed with our High Temperature Uniformity thermal chuck product line. The thermal chuck needs to be precise and able to reach the set temperature target of, for example, 125°C, but this temperature also needs to be uniformly spread over the entire chuck surface without too many variances.

Q: You will be attending this year’s SW Test in San Diego, where our CTO, Klemens Reitinger, will present our solutions for temperature regulation in high power wafer test. Can you tell us what the audience can expect to learn from our presentation?

Bernd: High Power wafer test can mean a few different things. It can be either testing of high voltage or current devices, low voltage CPU devices, or massive parallel testing of NAND or DRAM chips. What they all have in common is that it’s very tricky to accurately determine and control the temperature of the device under test. In our presentation, we will address exactly this challenge, explain why it’s so important, and present our data-based solutions to achieve accurate temperature regulation in each test scenario.

I’m very excited to attend the conference in person this year, and I think it’s great that the SW Test committee is providing an online option as well so that people that can’t travel can also access the presentations on-demand.

Want to watch our presentation at SW Test San Diego? Click here to register for the virtual conference, which gives you access to all the presentations on demand from Sept 2nd to Oct 2nd. And don’t forget to follow us on LinkedIn to get the latest news and updates from our company!