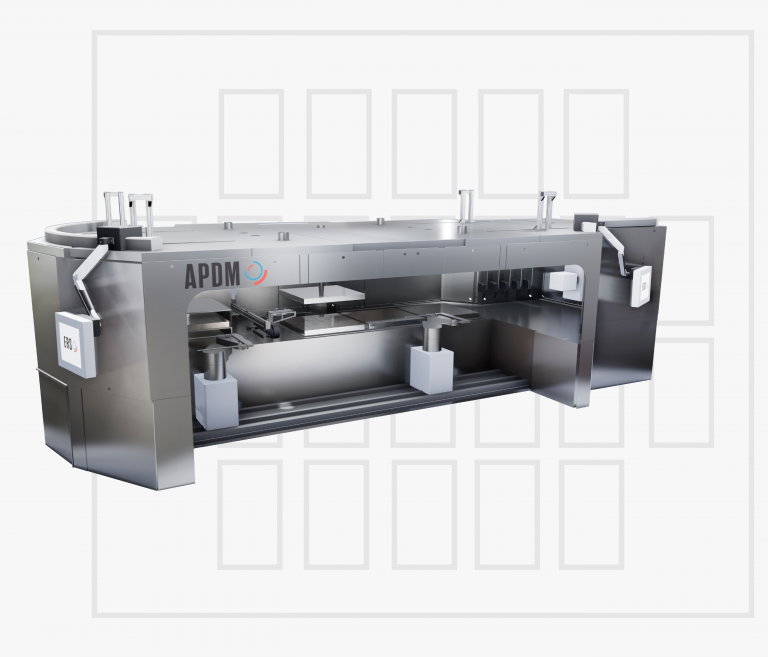

Automatic Panel Debond System

Automatic FOPLP panel debond system

Advanced thermal debonding solutions based on ERS’s TriTemp Slide technology.

DESCRIPTION

In-situ feature: Warpage Adjustment Tool

Following the success of the Manual Panel Debonding Machine (MPDM), ERS offers its automatic counterpart, the Automatic Panel Debonding Machine 650 (APDM650), the ultimate tool for high volume manufacturing of Fan-out Panel-level Packaging.

Features

- Optimized thermal debonding and detaping for large panel format up to 650 x 650 mm

- In-situ panel warpage control and inspection

- Multi-location panel frontside laser marking

- Fully automatic “warpage adjust only” mode

- Interactive user interface

- Customizable for factory automation integration

- Flexible handling for loading and unloading EFEM systems

The ERS APDM650 performs fully automated separation of panel and carrier („debonding“) for Fan-out Panel-Level Packaging (FOPLP) technologies. With the patented TriTemp Slide technology, a thermal process is applied to reduce and control warpage of the debonded, reconstituted panel.

“For large area FOPLP, debonding is a crucial step to the process integrity of the panels. Working with the manual debonder MPDM of ERS at Fraunhofer IZM since 2018 has taken FOPLP process development a big step further in that regard. It is exciting to see that PLP has now reached technical and process maturity and is ready for high volume manufacturing.”

– Dr. Tanja Braun, Group Manager of Fraunhofer IZM and Head of the Panel Level Packaging Consortium.

APDM650

TECHNICAL DATA

Warpage Adjust Only Mode

* Warpage output depends on product

** PPH is recipe dependent

SIZE

For special requirements, please contact us.