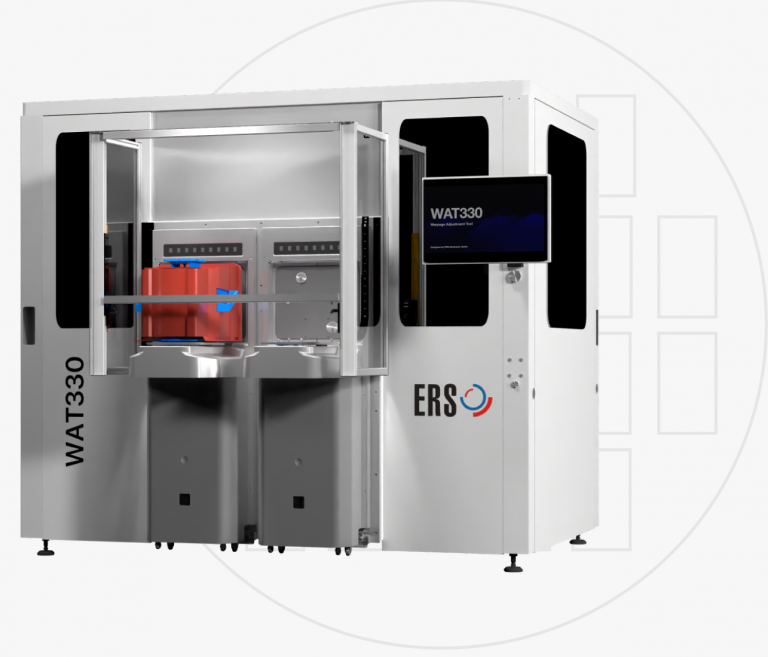

Automatic Warpage Adjust Tool

The WAT is a fully automated warpage correction tool, providing optimal results with ERS’ TriTemp Slide technology

Description

The ERS WAT is a fully automatic tool for the thermal forming of 200 mm (WAT200) or 300/330 mm (WAT300/330) FOWLP wafers. The specially-designed ERS TriTemp Slide in this system makes it possible to successfully form a wide variety of FOWLP wafers at various stages in their processing and the resulting wafer shape can be matched to the handling specifications of the downstream tool.

The ERS WAT is able to process up to four FOUPs in a fully-automatic operation. It is equipped with a Wafer-ID reader and an automatic warpage measurement station that enables a high flexibility with 3 separate operation modes.

The upgraded WAT330 comes with a HEPA filter system for cleanroom class 100. It is also fully compliant with the GEM300 SEMI standards and compatible with automated product loading and unloading. Another upgrade is the machine’s Nitrogen environment, which can reach down to 0.5% O2 level to avoid Cu oxidation. The new WAT330 also features strong vacuum thermal chucks for no-fail wafer handling.

WAT

Technical data

Dimensions

Facility Supply

For special requirements, please contact us.