MASTERING THE 5TH DIMENSION

Bringing an awareness of thermal influence in test and production and the experience to deal with its challenges.

Learn more about our technology, innovations and quality assurance.

Applied Thermal Excellence

Over 40 years of empirical research and applied thermal development means that we are not only able to solve problems that can be calculated, but also those that are only recognized intuitively. Our experienced design engineers predict mechanical and electrical influences related to temperature before simulation programs or prototypes confirm them.

Temperature

The Key to Mechanical Precision and Electrical Performance

As with all high-tech industries, the tools for the manufacturing and testing of semiconductor devices have to meet specifications for mechanical precision and electrical performance that become ever stricter. Simultaneously, production efficiency demands ever-larger substrate sizes and ever-shrinking critical dimensions. ERS engineers understand the interplay of temperature, mechanical precision and electrical performance to a degree seldom found elsewhere in the industry.

Investing in Future Technology

Development engineers make up over 25% of the ERS work force. Located in its own building at the ERS factory, the well-trained engineering team has access to state-of-the-art thermal imaging tools and the software tools in use throughout the industry.

Solutions Conceived, Tested and Manufactured in House

Over 95% of the production process of ERS thermal chuck systems can be accomplished within the walls of our factory near Munich, Germany. CAD designs from our engineering department are sent through the ERS network to control CAM machine tools making same-day protoyping a reality. The built-in quality of new products is a result of the proximity of the design engineer to the production floor. Qualified local sub-vendors are used later to control costs and reduce lead times once the system is mature.

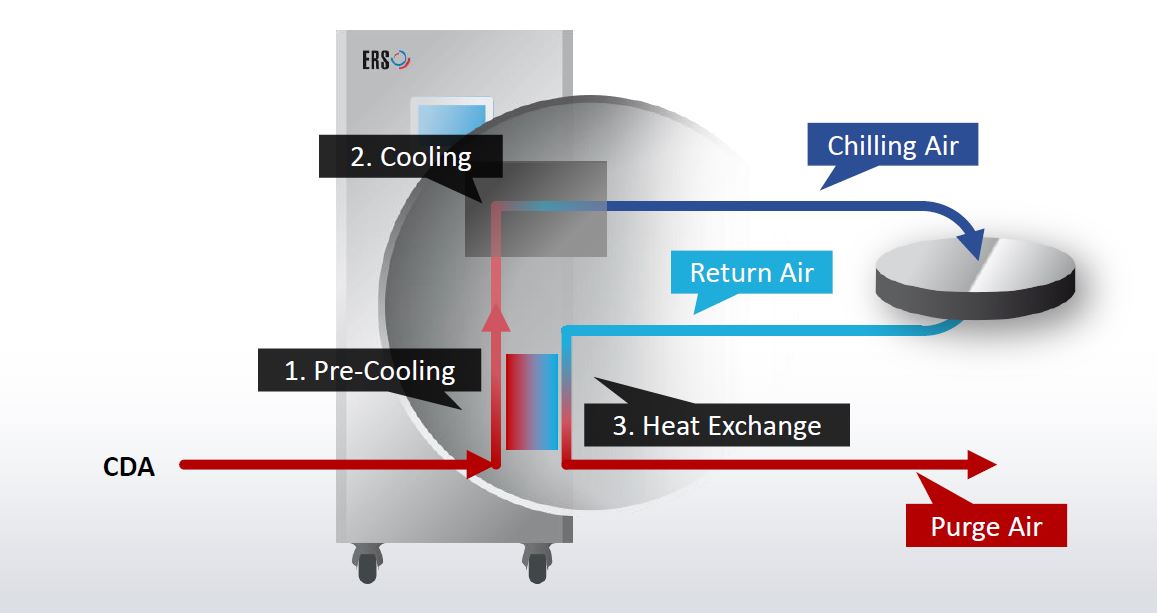

ACP Patented Efficient Heat Exchanging System

The core technology of the highly efficient AC3 is the patented ACP air management system. ACP extracts maximum effect from the chilled coolant air in a two-pass cooling operation. The expended super-dry, clean coolant air is then available as a cost-saving purge gas to prevent icing on the wafer and the surrounding area.

Virtually every semiconductor manufacturing line has a ready supply of pressurized clean dry air (CDA) easily accessed at the wall utilities behind the equipment in the factory. Unlike water and other cooling liquids (including water-glycol and synthetic cooling agents), when air is used as the coolant it does not impose limitations with respect to the temperature ranges needed for semiconductor test.

Turbo-cooling and prevention of icing

With the patented ACP turbo-cooling effect used in the AC3 system, deep-cold testing can be achieved even though air is the medium transferring the temperature to the test area.

When the required test temperature is below +15°C and especially when testing is down in the deep cold ranges of -40°C and below, preventing frost in and around the probe area becomes critical. Large amounts of CDA (or other very dry gas like N2) are necessary as an environmental purge to prevent icing on the wafer and inside the probe area. Failure to reliably prevent frost in the probe area can result in the destruction of expensive electrical probes used during cold wafer test and/or damage to the electronics of the wafer prober when the ice melts.

This need for environmental dry air (or gas) purge exists independent of whatever coolant is used to achieve the temperature in the wafer chuck.

Maximum efficiency

The patented heat exchanging system on the AC3 extracts maximum cooling from the chilled air and then utilizes that same air to purge the test area. This rewards the user with significant cost savings in the consumption of compressed air and mains power.

In addition to the advantage of the turbo-cooling and re-use of exhaust air as a dry air purge, ACP has the smallest footprint in the industry compared to the cooling performance. With no need for monthly maintenance procedures and regular topping-up of liquid coolant levels, the AC3 is by far the most reliable system on the market.

Quality Management

Quality is the inevitable outcome of ERS‘ philosophy of design, manufacture and customer support. The old saying that our customers’ success is our success is embraced by the entire ERS team. We proudly note that 85% of ERS chuck systems built since 1971 are still in use today.

Constant and accurate quality assurance

The renowned ERS product quality is monitored by a fiercely independent Quality Assurance group. The QA group’s direct and immediate in-house access to all design and manufacturing groups allows the fastest and most comprehensive detection of quality problems well before final test is complete. The QA department tests and documents all operations of each system and performs aging procedures where required. Adherence of the QA department to quality procedures is checked on a regular basis.

Quality awareness from the very beginning

However energetically and thoroughly quality control is performed at the ERS QA group, the awareness of quality during the design, prototyping and beta of a new system remains as the most significant factor in product quality. ERS’s four decades of wafer chuck experience comes into play during development decisions. We build for quality from the beginning.

Implementation and roadmap support

ERS technical support personnel communicates regularly with the customer before, during and after delivery of an ERS system. This is the case even when the customer is reporting no problems with the system. ERS philosophy is to advise its customers on the use of its products and detect future customer needs at an early stage.

Monitored quality

The headquarters of ERS in Germering ensure a constant traceability of every project according to TÜV-certified ISO 9001:2015 quality management procedures.

TÜV-Certificate for ERS’s headquarters in Germering:

Download Certificate (PDF)